We consistently get two questions in the shop from folks that are new to the truck scene; Are lift kits bad for your truck, SUV or Jeep, are lift kits safe, and can lift kits cause problems? The TL;DR version is that when a lift kit is properly installed, it will not cause problems with the vehicle. Let's dive into that a little bit more and give you some warnings about what can happen.

Lifted 2020 Ram 2500

To start off, from the factory, these trucks and components aren’t going to be very impressive. These trucks are built by accountants, and will be built to meet the needs of 85% of the truck buyers; in a cost effective way for the manufacturer. However, even the off-road editions of these trucks like an AT4, TRD Sport, Rebel, or a Tremor will still include things like a twin-tube shock, and will still use the same steering and suspension components from the standard models that they are based off of.

Are lift kits safe?

In the last 25 years, cars and trucks have become technological marvels. Highway speeds have increased, pickup trucks are designed for comfort and ride quality rather than strictly for work, and modifications have become very mainstream. The lift kits of the late 20th century that seemed to be slapped together with little regard for ride comfort are a thing of the past. Lift Kit makers have to compete in the realms of ride quality, performance, looks, and warranty.

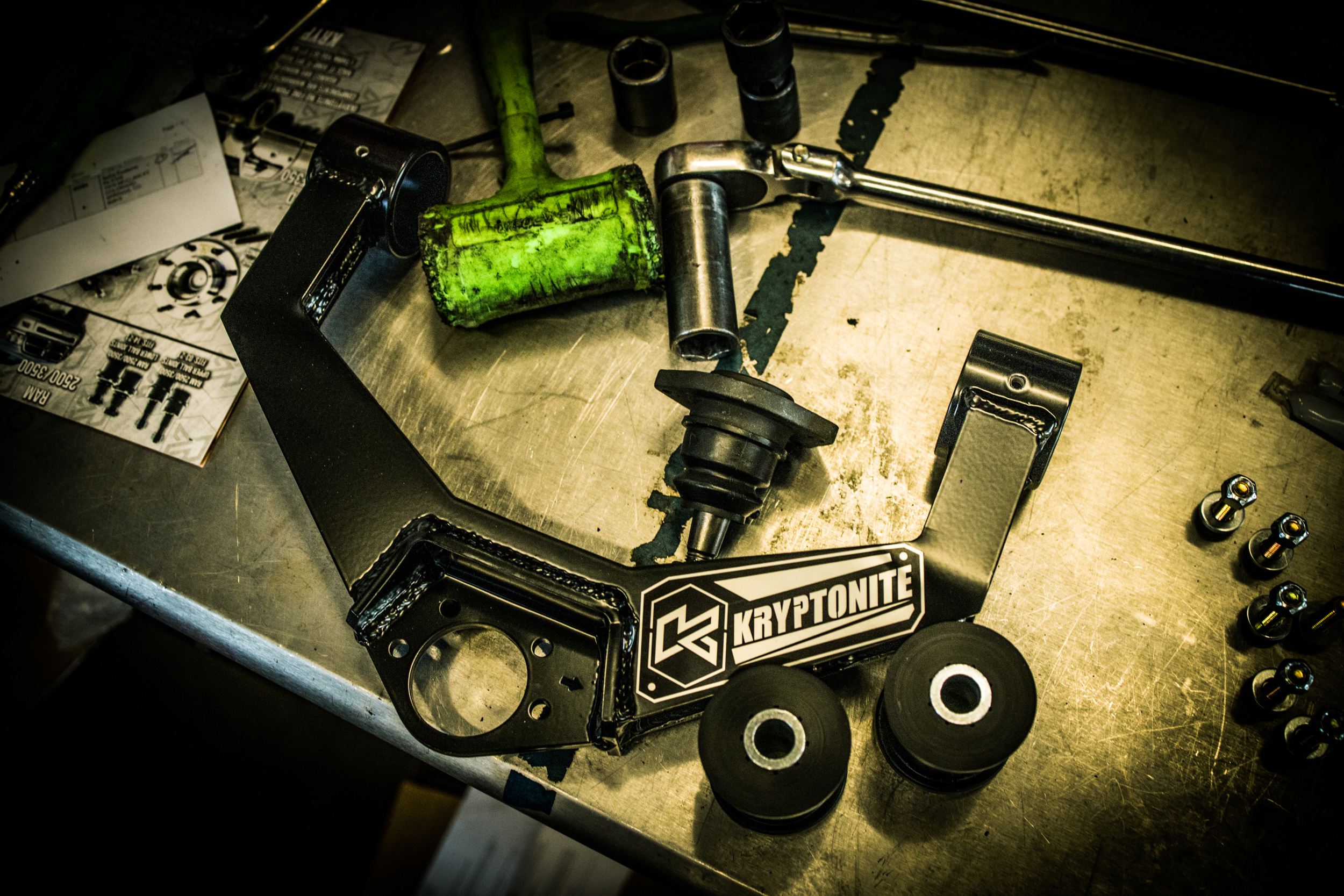

Powder Coated Cognito Control Arm

There are some tips that we have to make sure that your experience with your very own lifted truck are the best. We are glad that you have come to this industry to make sure your truck is as unique as you are; and we want you to stick around for the long-haul!

Tips and tricks to ensure safety and longevity

1). Watch your maintenance items within the truck. The new shocks and struts, aside from your top performance line shocks, will follow very closely to your factory intervals for replacement. The industry standard is about 60,000 miles.

When you are running bigger and heavier-than-factory wheel and tire combos, you can stress some of the factory components. Even stock; GM trucks will go through hubs, pitman arms, idler arms, ball joints, CV axles etc. to just name a few wearable parts. The independent suspension Fords, Rams and Toyotas will see some of the same problems as they age. The Solid front axle Rams and Fords, as well as Jeeps, will go through ball joints, track bars, sway bar bushings and things of that nature. Keep an eye on these components as you are running these heavy setups. Often-times we will use the wearing of parts as an excuse to upgrade to a more durable or a serviceable part. But by no means are these problems going to occur monthly. It will still follow very closely with the factory intervals.

2). Do not try to make a franken-kit. Some of our customers begin their process and they want to buy components from many manufacturers, which can put them in a compromising position. Generally with these kits, you can run up to a 3” or a 3.5” lift with the stock frame set-up. Once you get into the 4”+ range, you are needing to go to bigger kits that will drop your differentials, transfer case and front end components in a way that will not put factory parts at an extreme angle. These big name kits in the industry are researched and developed as full suspension systems. They are designed to work within the angles that the manufacturers set as “within spec”. Experts within the industry will know which components and kits can compliment one-another so be sure to ask questions!

3). Know your own mechanical limitations. It is easy to look at an install labor quote and think that you can try to save some money by doing it yourself. While I have seen many of our customers accomplish this, a six inch lift kit with a crossmember cut and drop should not be your first foray into suspension work. Even as the marketing guy in this shop, I sometimes will crack into my own projects on my own vehicle, but can quickly be reminded of my limits.

The other issue with the DIY is the alignment. Anytime we are pulling spindles, lifting, messing with tie rods and all of that, we are going to want to do an alignment immediately after. Here in our shop, the alignment rack is maybe a 30 foot drive from where these trucks get lifted. If you are lifting at home and driving to a shop, you may start some bad wear patterns in your tire; even on your short drive. Once a wear pattern in your tires starts, that pattern will not stop.

4). Pay close attention to your wheel measurements. Hub-centric is the best way to ensure that your hubs last. If you are buying spacers, make sure they are hub-centric. This will keep you from sheering off your lug studs and losing your wheel. Be sure that you have the right center bore. By the same token, make sure to utilize the correct hub rings on your custom wheels. This is especially important with a bolt pattern like the 6x5.5" (6x137.9) which is the most common bolt pattern for these trucks. It is the bolt pattern for the GMC, Chevy 2019+ Ram and 2022+ Toyota Half Tons. It is also the same bolt pattern as the Toyota Tacoma, as well as the Ford Bronco and Ranger. Each of these vehicles have a different hub bore. Having the incorrect ring will have the wheels vibrating and can drastically shorten the life of your hub bearings

In COnclusion

The custom truck market is moving at a rapid pace and it is moving in a great direction. These kit manufacturers have risen to the occasion by increasing their quality, by stepping up their warranties, and creating many options for kits to appease even the most discerning of customers. The industry is more accessible than ever before and now is the time to lift your truck!